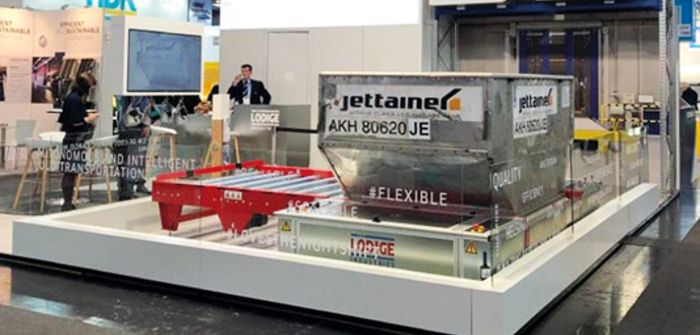

Germany’s Lödige Industries has unveiled its latest innovation for intelligent automated Unit Load Device (ULD) transportation, a computer-controlled wheel-based carrier that features a 5ft and 10ft model for different sizes of ULDs, with the larger variant capable of lifting and transferring palletized loadings.

Taking advantage of data-based functions to assign routing precisely via warehouse management systems, the faster and highly reliable automated guided vehicle (AGV) will boost operational efficiencies in baggage and cargo transport. The battery-powered load carrier enables operators to connect the various terminal areas in a flexible and scalable way, establishing, for example, an effective link between landside-based truck docks and airside-based ULD storage or other repetitive intra-terminal transfers.

The driverless AGV will enable operators to free up staff for higher value assignments. Furthermore, it is an effective tool for use when space is scarce and flexibility is critical. The AGV has the potential to lower fixed costs by making floor-mounted roller conveyors redundant; these have traditionally been seen as the most economical way of conveying air freight.

“We are pleased that we can offer our customers a product that will foster sustainable operations and significantly improve terminal efficiency,” said Björn Ussat, director airport logistics solutions at Lödige. “The ULD AGV is the natural extension of our product range, as we can offer even more flexible terminal configurations to our customers.”

At a speed of 3m/sec, the 10ft model can handle various ULD contours and runs one shift on a single battery charge. Its maximum load capacity of 6,800kg (15,000 lb) covers all possible 10ft-ULDs. The 5ft model carries loads up to 1,588kg (3,500 lb) for 12 hours straight. Customers are able to order the 5ft model immediately, while the 10ft device will be available from the summer of 2020.