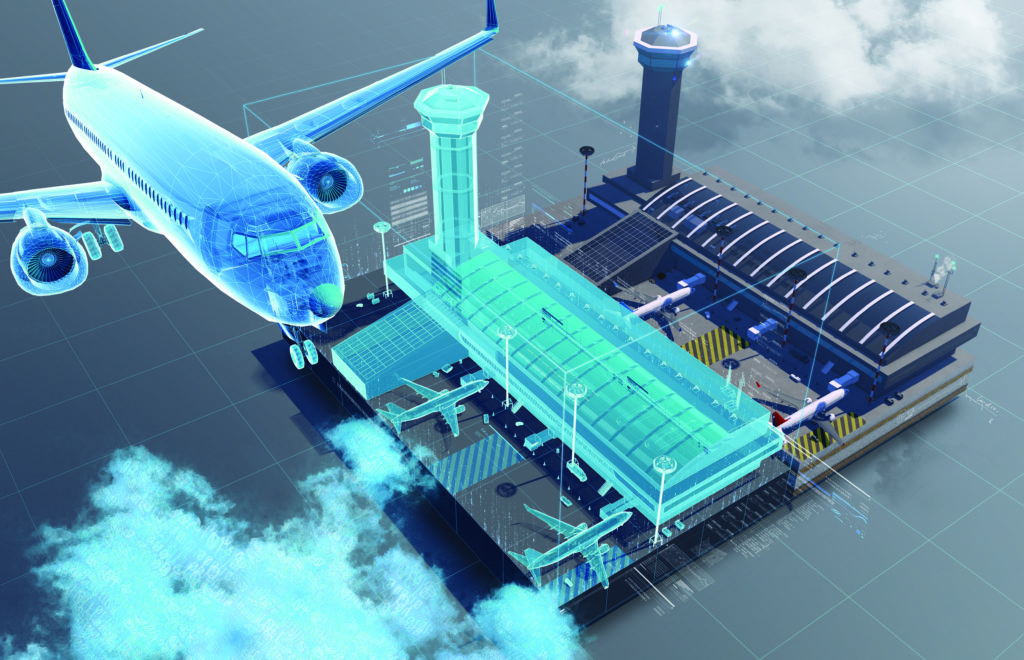

What role do digital twins play in helping airports improve operations now and in the future?

A digital twin is the virtual replica of a physical asset, process, place, system or device. Essentially a computer program, it uses data as the input and produces simulations of how its assets or processes will be affected by these inputs. Such real-time analysis and predictive modeling offer up ‘what if’ scenarios that are both faster and cheaper than real-world testing, creating insights into how to improve operations and increase efficiency. According to the Gartner Group, by 2021 half of all large industrial companies will use digital twins. As airports get busier, the need for improved asset management is crucial to optimize safety, security, efficiency and passenger experience.

“Digital twin technology has been around for about 15 years,” says Kevin O’Sullivan, lead engineer with SITA Lab, a world leader in digital twin modeling. “However, it has only recently become possible at airports thanks to Internet of Things (IoT) sensors that gather data from the physical world and send it to machines to reconstruct.”

Andy Smith, director of product management, building and structural design with Bentley, a software development company that recently helped create a digital twin at Governador Jose Richa Airport in Brazil, adds, “A digital twin can be used in all stages of the asset lifecycle, from planning through to operations. They can help ensure assets remain fit for purpose. Machine learning (ML) and analytics for simulation can optimize current operations and future expansion of existing assets. During operations, you can simulate terminal performance for a special events or adjustments to timetables and increased passenger volume.”

Single 3D model

Amsterdam Schiphol is currently rated the 11th busiest airport in the world and last year saw a rise in passenger numbers of 3.7%. As such, the need for strong asset management is crucial to optimize safety, efficiency and passenger experience. Five years ago, it began using building information models (BIMs) to bring all aspects of its buildings and assets into a single visible 3D model. This model can be accessed, edited and easily shared in real time. As large amounts of data go through a terminal, the model becomes more accurate.

“At Schiphol we started working on the digitization of asset management because we wanted to improve the efficiency and effectiveness of all our assets by making better and smarter decisions during the asset’s lifecycle,” says Alex Worp, strategic advisor on digital asset management at Schiphol Airport. “We started with analyzing the existing information in the databases and improving their quality. After that you can begin working on a linked data platform in which all your asset data – geographical and non-geographical information and documents – are stored and continually updated through IoT.”

Worp claims that there are many usages for digital models with good quality, consistent and verified data, but that the most common are people flow during peak times, fire safety analysis, and prediction of the flow when more or larger airplanes arrive. He estimates that via the use of its digital twin, the airport should be able to save 5-10% on the maintain-and-operate phase of an asset and 10-20% on projects.

“The biggest benefit is the cost reduction, more effective and efficient usages of assets, and the processes that develop and maintain them,” Worp adds. “Digital twins take you from preventing maintenance to predicting it.”

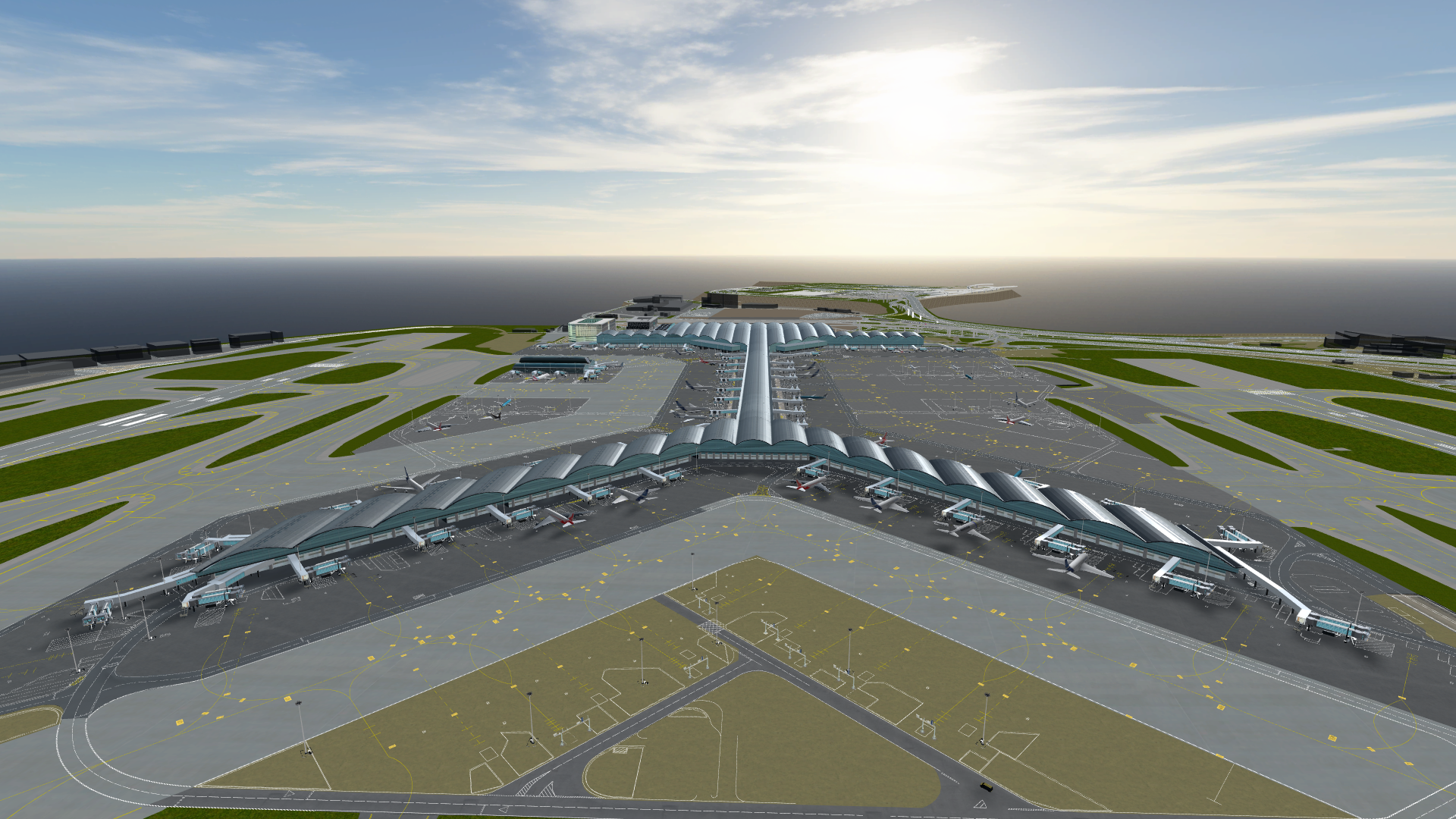

Hong Kong’s vision

Hong Kong International Airport (HKIA) is developing itself into a smart airport, which aims to apply innovation and technology to create an enjoyable and hassle-free experience for passengers, as well as enhance the operation efficiency. Creating a digital twin of HKIA is one of the innovative programs of the smart airport vision.

“Our digital twin is a virtual 3D model in which data from different sources can be integrated, made available instantly, visualized in a human-centric interface and analyzed to make predictions in an explainable way,” says Andy Bien, chief information officer at Airport Authority Hong Kong. “Digital twins are also constructed for new construction projects to provide a lifelike look of the design and amenities to facilitate better planning and design adjustments.”

The creation of HKIA’s digital twin first started with the BIMs of HKIA linked with various operation data from the airport’s asset management system, which is integrated with a geographical information systems (GIS) map to create the static state of the digital twin. A unity engine – a development platform designed to integrate and create 3D models also used in video games and architecture – is then deployed to navigate the 3D model of the airport in a photo-realistic manner. To make the digital twin alive, the model is fed with real-time data from IoT devices deployed throughout the airport. This is coupled with simulation tools, corporate applications and an enterprise analytic platform. This way, HKIA can literally predict what the airport will experience in the future.

“The virtual model has been completed for the areas of Terminal 1 that are accessible by passengers, while remaining areas of the airport will be added to the replica in stages,” says Bien. “The digital twin’s lifelike visualization helps the airport authority streamline our design review for new construction projects, especially for off-site construction methods that require more precise planning. Also, using predictive analytics, the digital twin can provide maintenance alerts that are useful in effective resources deployment, resulting in cost savings and improved services.”

The supplier view

Atlas Industries Vietnam worked closely with HKIA on the development of its digital strategy for deploying a digital twin at the main terminal. “Winning the bid was the easy part,” says Steve Reid, operations director at Atlas. “Then came an in-depth gap analysis of years of 2D data in the form of information that was far from accurate. The airport was already split into zones and we mimicked those zones as far as we could with a multidiscipline BIM software model containing architectural, structural and mechanical, electrical and plumbing services.”

All nine floors of the terminal were captured in the digital twin, from the apron level up to the roof, encompassing arrivals and departures with a heavy emphasis on passenger-facing areas. This gives a single ‘source of truth’ view of the conditions of the airport, and the assets contained within. By having this information, the airport is able to maintain itself efficiently via its operation and maintenance departments knowing exactly what assets they have and where they are located.

Atlas’s goal is for digital twin technology to start making recommendations based on what the data shows will happen. The airport can then set its own rules about how those recommendations are actioned. Some will be handled automatically, while other decisions will always need human input, particularly during times of heavy disruption.

Meanwhile SITA Lab is testing out its digital twin project at a major East Coast US airport. It has a 3D model of the airport in real time running on an 86in touchscreen in the operations room, with a conversational interface for control providing an interactive situational awareness across the airport, airlines and other stakeholders.

“We take the concept of the digital twin and apply it across an entire airport to model operations,” says O’Sullivan. “This means airfield, in-terminal baggage, passengers, staff and equipment. What we are doing is bringing together siloed information and presenting it in one place. The result is improved decision making based on a holistic view of the airport’s operations. As well as showing what is happening now, we can select a moment in history and play back what occurred previously. It is a very effective way of investigating the handling of disruption and to identify what can be done better next time.”

O’Sullivan adds, “Ultimately recommendations made by digital twin technology will help inform that decision making. The technology will learn which recommendations are typically accepted and suggest a new rule to make the process even more efficient. A fully functioning digital twin of an airport is still some time off, but as we build it out more widely and deeply, the full extent of its potential is becoming clear.”

Advice for the twin-curious

“I would tell the airport owner-operator to start with the end in mind,” says Bentley’s Smith.“They must identify the end user and the intended use of the digital twin. They should also know what problem they are attempting to solve. This will lead to what types of maps, models, drawings and engineering data should be collected and how it should be presented.”

“Engage all key stakeholders within the airport in order to see how they use the data,” adds Atlas’s Reid. “Establish standards and protocols for model management and updating. Future-proof the data in the model and do not rely on proprietary software; the airport will be around long after the software. Upskill staff in the use of manipulation of the data and models. It will need a step change in terms of people, process and technology. If unsure, seek professional help to map out a strategic roadmap for the digital transformation of the airport prior to deploying a digital twin.”

SITA Lab’s O’Sullivan continues, “There is significant potential in digital twin technology and it is certainly something all airports should be looking at. However, a digital twin of an airport can only be truly effective if every available piece of data is used, making it important to ensure you have buy-in from all stakeholders involved in running the airport. If you don’t, you won’t get full value from your investment.”

This article was originally published in the September 2019 issue of Passenger Terminal World