Kevin O’Grady, associate director at Arup, explains how technology is being used to optimize the airport design and construction process by moving from 3D to 7D modeling

In construction, where projects are continually growing in scale and complexity, digital technologies offer huge potential for improving productivity. Currently, it is estimated that the typical large project across all asset types overruns its schedule by an average of 20% and exceeds its budget by 80%. The application of digital technologies has been shown to reduce cost and schedule overruns by an average of 10-15%, and by even more on complex projects.

Overall, however, construction is seen as lagging behind other industries in the adoption of new digital technologies. The industry’s spending on R&D of less than 1% of turnover lies way behind other industries such as automotive (3.5%) and aerospace (4.5%). Its investment in information technology is also below the 1% figure.

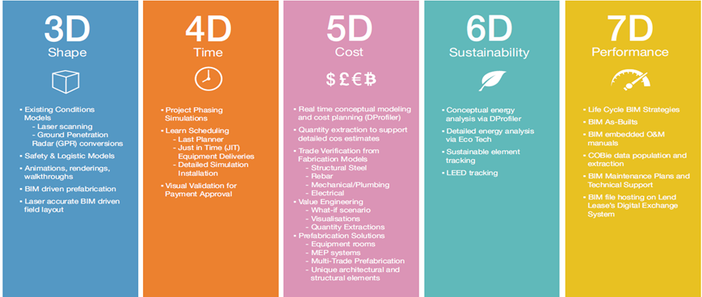

Recent innovation around airport design and virtual modeling demonstrates in full the potential that new technologies hold to enhance the construction process. New modeling tools now allow for the integration of multiple workstreams on a common data exchange, alongside visualizations, which enables the real-time calculation of project cost and time, energy, sustainability, risk and long-term performance, during design and construction. This move, from 3D to 7D modeling, means greater efficiency and scope for substantial time and cost savings as a project progresses.

Creating data driven models and collaborative projects

Moving from 3D to 7D modeling – integrating all disciplines together on a common digital platform – enables real-time dataflow between each discipline. This has the potential to create an enhanced, more efficient design and construction process. An integrated project link provides interoperability for other functions to come together.

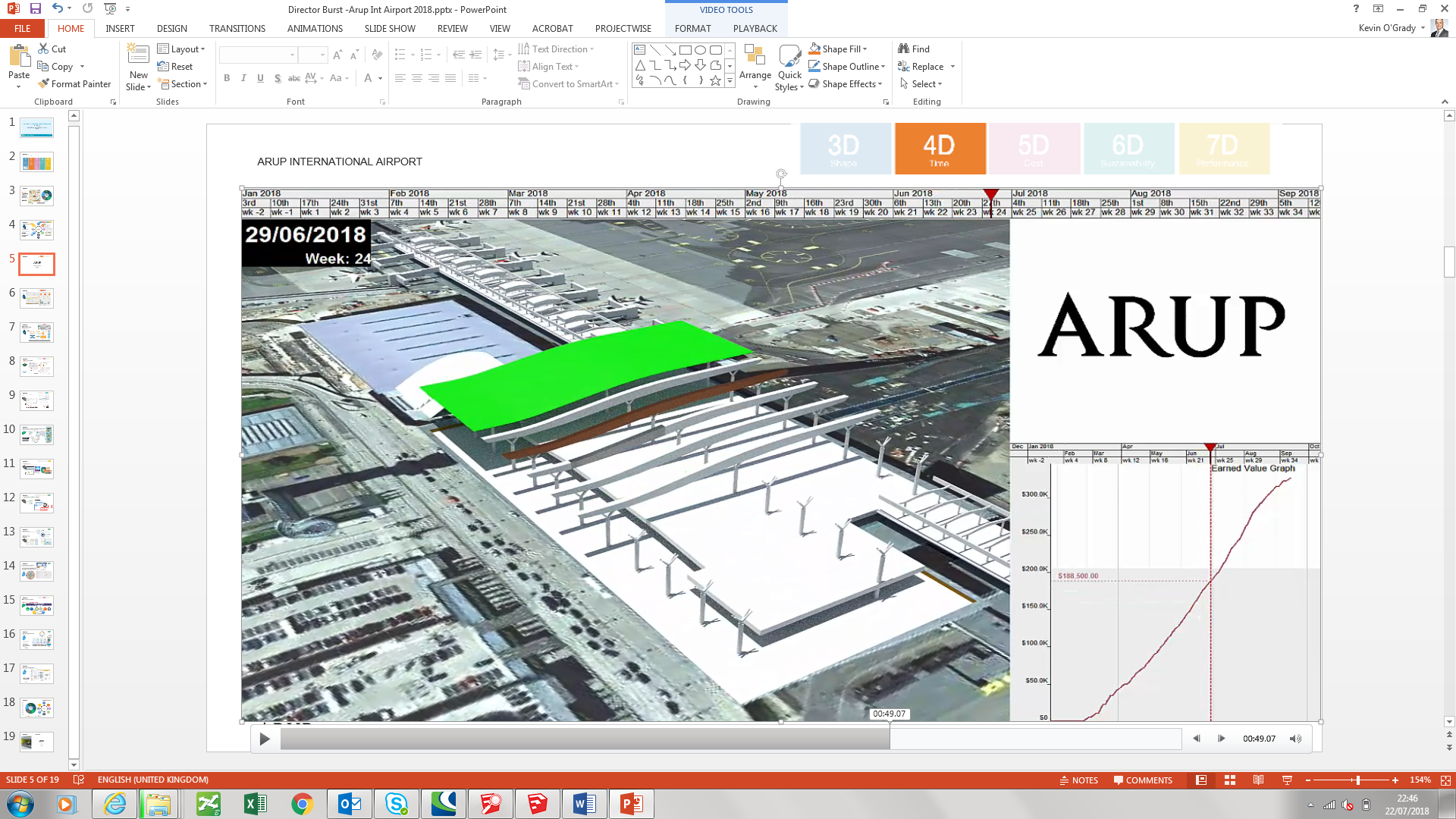

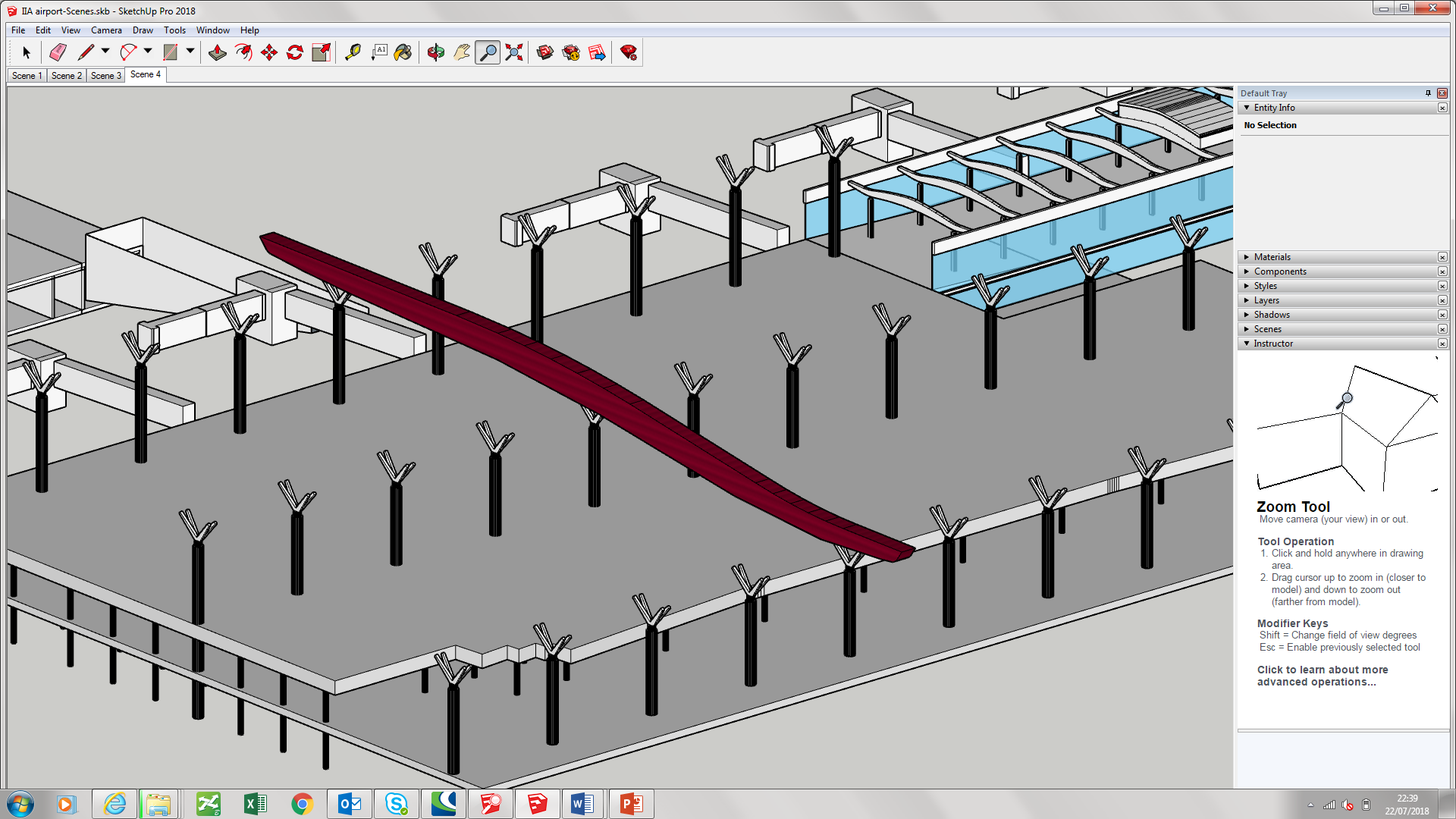

A new tool developed by the aviation team at global engineering consultancy Arup – the Arup International Airport integrated platform – puts these new techniques into practice.

Embodying the principles of ‘Total Design’, whereby all design decisions are considered transposing across disciplines, it allows for a new level of collaboration, bringing together the disciplines involved in design, construction and operation, and plugging them into one platform. The company wants to set a new benchmark for how airports are designed.

SMART contracts and circular economy

These new modeling tools also allow for the trialling of the use of Distributed Ledger Technologies (DLT) and blockchains, SMART contracts and the principles of the circular economy, whereby resource input and waste are minimized.

A partnership of leading experts including RICS, SAP, IBM, Network Rail, Tata Steel, Arup, Cognitive+, Process Innovation Forum and Nomitech, as well as many leading UK universities, have come together to form a Construction SMART Contracts Committee, exploring the journey of a steel beam on a SMART contract, to demonstrate how it all works, and the benefits, in practice:

• Design specification will request in-depth data from the manufacturers and supply chain, SMART contract will use DLT to monitor contract clauses;

• DLT will provide evidence of the flow of payments throughout the supply chain, providing increased trust and transparency, an issue widely debated by governments and clients globally, to ensure an equitable environment exists within the construction sector;

• IoT sensors will monitor the deflection of steel over time, for example measuring performance for future steel applications;

• The use of DLT to record and tag assets such as the steel beam means that at the end of life, the steel composition is exactly mapped, enabling accurate re-life of the steel; thus, maximizing the recycling of key materials and reducing waste.

Developing the future engineer

Leading UK universities have been working to create future engineers with an understanding of these new technologies and design tools, to ensure they can take full advantage of them. In collaboration with Professor Linda Newnes at Bath University, Bristol University and University of the West of England, under EPSRC funding, companies such as Arup are involved in creating the foundation courses for future engineers with the ability to learn, refine and study the function of digital assets, human-machine interaction and whole life modeling. This five-year study is set to aid the rapid uptake of new processes and skills that transdisciplinary engineers will need in the future.

Looking forward

Technology plays a big part in today’s culture, allowing for the democratization of knowledge. Information is now more widely accessible than ever before, meaning a fully collaborative and transdisciplinary approach is now possible. These new tools allow us to bring together all elements and disciplines involved in the design process in one place, driving efficient and improved performance.

This is an exciting and transformative time for the aviation and construction industry in an evolving world; those who understand the benefits of data interaction and who are outcome-focused, will have the leading edge.